Horticulture Guruji

Exercise 11

To study the oil extraction method of MAPs

-

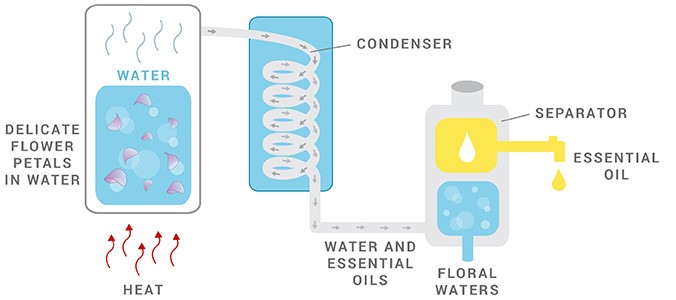

Water Distillation / Hydrodistillation

In water distillation, the starting material is immersed in water and boiled using direct heat, steam coil, or steam jacket. This process requires the material to be kept in motion to avoid degradation of dense material that may settle to the bottom of the apparatus. Essential oil is collected along with steam then separated post condensation. The required products can be easily extracted from finely cut material or powders, which would be difficult to achieve with steam distillation as it results in the formation of lumps that are partially impenetrable to steam. Another advantage of this method is the ease and relatively low expense associated with setup. On the other hand, it is a slow process and there is the degradation of required products via hydrolysis or polymerization of sensitive components due to prolonged heat exposure.

Delicate flowers such as roses and orange blossoms would clump together when introduced to steam in the distillation process, so the most effective method of extraction in this situation is to submerge fragile plant material in pure boiling water instead. The water protects the extracted oil from overheating. The condensed liquids cool down and separate from each other. The remaining water, which can sometimes be fragrant, is referred to by several names including hydrolase, hydrosol, herbal water, essential water, floral water, or herbal distillate.

-

Water and Steam Distillation

Combined water and steam distillation are similar to water distillation, however, the material in question is not in direct contact with water but rather placed on solid support above the boiling water so that steam can directly pass through it. For best yields, the material should be evenly distributed so that there is efficient contact with the material by steam. Some setups increase their efficiency by the addition of a cohobation tube which ensures that after condensation and separation of the essential oil, water is returned to the still to be reboiled, thereby ensuring that there is enough water in the system to ensure complete extraction. This method also ensures minimal loss of oxygenated components including phenols. Compared to water distillation, this method gives greater yields, oil quality is more reproducible, and the process is quicker than water distillation.

-

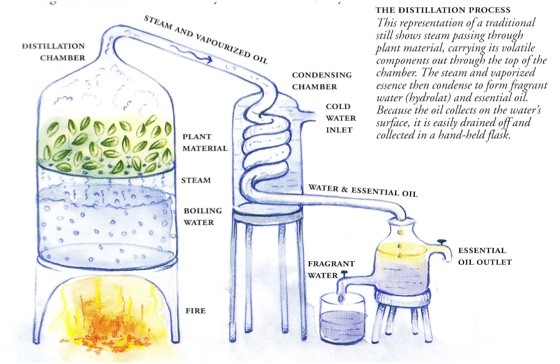

Steam Distillation

Steam distillation is one of the oldest extraction methods, invented by the Arabs in the ninth century.

One of the most widely used methods of extracting essential oils from their sources is steam distillation, and it is one of the preferred methods due to its low cost. This is a low-temperature distillation method that allows for the separation of nonvolatile, water-immiscible substances at temperatures below the boiling point of individual constituents. This leads to the preservation of components that may be disrupted at high temperatures.

In the case of essential oils, the procedure consists of passing water vapour at low pressure through a tank (called alembic) filled with aromatic plants. The steam naturally captures the volatile molecules that are contained in the plant, which then travel through a cold-water refrigerated serpentine and condense themselves into a liquid. Upon exit, elements of different densities are separated with the help of an “Essencier” and essential oil and floral water (also called “hydrolat”) are obtained. The following diagram summarises the process:

The Process

The steam distillation process for extraction of essential oils from plant material consists of 4 basic parts.

The Steam Generator or Boiler

Capable of producing saturated steam at pressures of 50 to 150 psi. High pressure is required to raise the steam temperature above 100C (in the region of 150C.)

The Retort or Still

Contains the plant material. High-pressure steam is passed in at the base into a void beneath a perforated grid witch supports the charge of plant material. The steam passes through the plant material heating and saturating it with water. The resulting vapour a mixture of steam and essential oil vapours (the oil is for the most part insoluble in water) passes out at the top and is conveyed to the condenser.

The Condenser

The vapours from the retort are cooled by passing down a long spiral or bundle of tubing cooled by being immersed in a flow of water. The condensate runs by gravity into a container in which the oil and water separate by virtue of their different specific gravities. This is the Separator

The Separator

The mixture of condensed oil and water runs into the separator where the lighter insoluble oil floats on the surface and accumulates slowly and from where it is drawn off periodically. This is the Essential Oil. The water – or rather a water that contains the more water-soluble constituents extracted by the steam, known as the hydrolat or ‘floral water’ – is drawn off continuously from the bottom of the separator.

- Solvent extraction

This method employs food-grade solvents like hexane and ethanol to isolate essential oils from plant material. It is best suited for plant materials that yield low amounts of essential oil, that are largely resinous, or that are delicate aromatics unable to withstand the pressure and distress of steam distillation. This method also produces a finer fragrance than any type of distillation method.

Through this process, the non-volatile plant material such as waxes and pigments, are also extracted and sometimes removed through other processes.

Once the plant material has been treated with the solvent, it produces a waxy aromatic compound called a “concrete.” When this concrete substance is mixed with alcohol, the oil particles are released. The aforementioned chemicals used in the process then remain in the oil and the oil is used in perfumes by the perfume industry or for aromatherapy purposes.

-

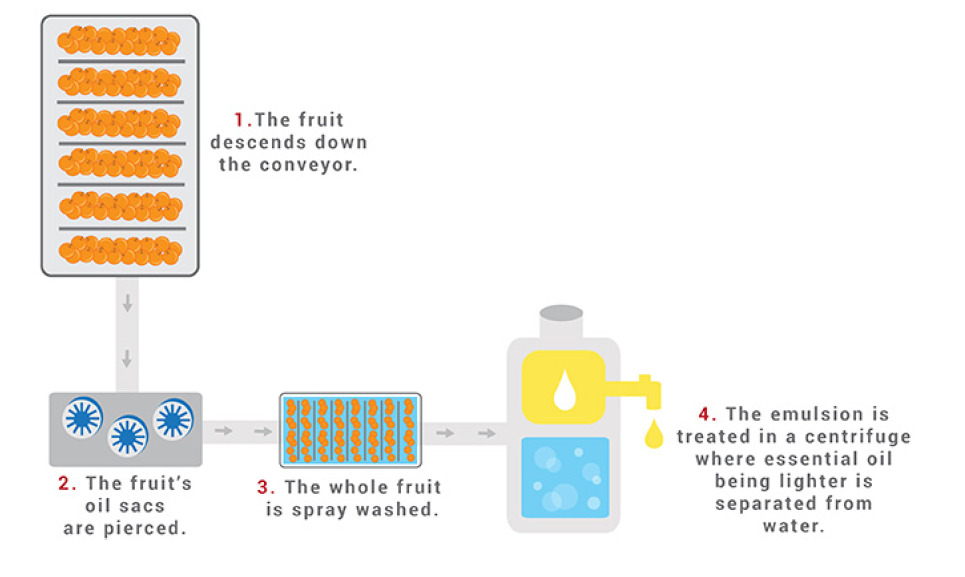

Cold Press Extraction

This method is also called Expression or Scarification and is used for citrus peels in particular.

- The whole fruit is placed in a device that mechanically pierces it to rupture the essential oil sacs, which are located on the underside of the rind. The essential oil and pigments run down into the device’s collection area.

- The whole fruit is pressed to squeeze out the juice and the oil.

- The oil and juice that are produced still contain solids from the fruits, such as the peel, and must be centrifuged to filter the solids from the liquids.

- The oil separates from the juice layer and is siphoned off into another receptacle.

6. Maceration

Macerated oils are also referred to as infused oils. They are created when carrier oils are used as solvents to extract therapeutic properties from plant material. The benefit of macerated oil above distilled oil is that more of a plant’s essence is captured in the oil, because it captures heavier, larger plant molecules than the ones captured in the distillation process. This keeps the product closer to retaining more of the plant’s valuable offerings.

The ideal plant material to be infused will be harvested so that it is as dry as possible, as any plant moisture will cause the oil to become rancid and will encourage microbial growth. Adding 5% of Vitamin E oil or Wheat germ oil (which is high in Vitamin E) will prevent rancidity.

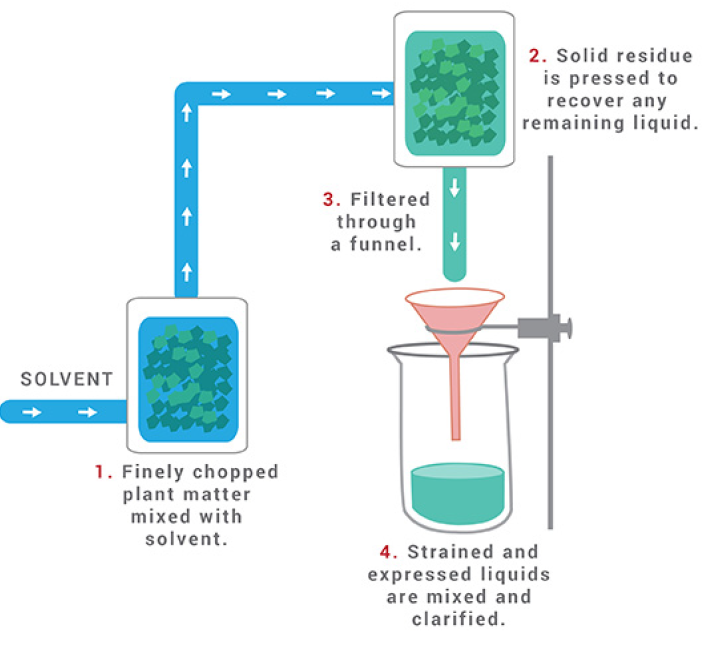

Maceration Process

- Plant material is finely cut, crushed, or ground into a moderately coarse powder.

- Plant material is placed in a closed vessel.

- Solvent (Menstruum) is added.

- The mixture is allowed to stand for 1 week and is shaken occasionally.

- The liquid is strained.

- Solid residue (Marc) is pressed to recover any remaining liquid.

- Strained and expressed liquids are mixed.

- Liquids are clarified through filtration or subsidence.