Jelly is a semi-solid product prepared by boiling a clear, strained solution of pectin-containing fruit extract, free from pulp, after the addition of sugar and acid. A perfect jelly should be transparent, well set but not too stiff, and should have the original flavour of the fruit. It should be of attractive colour and keep its shape when removed from the mould. It should be firm enough to retain a sharp edge but tender enough when it is pressed. It should not be gummy, sticky or syrupy or have crystallized sugar. The product should be free from dullness with little (or) no syneresis (weeping) and neither tough nor rubbery. The FPO specification for jelly is the final product should have 65% solids, 45% fruit extract, and 0.5-0.75% acid.

Guava, sour apple, plum, karonda, wood apple, papaya, and jack fruit are rich in pectin and generally used for the preparation of jelly. Pineapple, strawberry grapes, etc. can be used but only after the addition of pectin powder because these fruits have low pectin content. The preparation of jelly is similar to that of jam.

Procedure

- Selection of fruit: – In the preparation of jelly, the main step is a selection of fruit. The fruit is a select deep color, mature fruit and fruit can not be overripe.

- Washing: – The fruits are washed with clean or plane water

- Cutting into thin slices

- Boiling with water for extraction of juice

- Addition of citric acid during boiling

- Straining of extract

- Addition of pectin: – We know pectin is a structural component of jelly. We should be careful while the addition of pectin. Some pectin is already present in fruit so first its amount is detected and then rest is added. Because a high quantity of pectin may give a firm and tuff jelly if it is less the jelly may fail to set. 0.5 to 1% pectin of good quality can be used.

- Pectin Test

-

- Alcohol test: – In which the alcohol is added to the juice extract if clump form, the pectin is high if fragment form, the pectin is medium and if dissociates from the pectin is low.

- Jell meter test: – In which the juice is filed in jell meter allowed to flow in specific time and amount of extract is noted and then calculate.

- Addition of sugar: – Sugar should be added according to the pectin test in 1 liter of extract. If too much sugar is added it results in a syrupy or highly soft jelly

- Cooking: – In preparation of jelly cooking should not be below the endpoint. If the cooking is stopped before the total soluble solid reaches 65%. The jelly may remain syrupy and highly soft jelly should not be cooked beyond.

- Judging of End Point: – Boiling of jelly should not be prolonged, because excessive boiling results in greater inversion of sugar and destruction of pectin. The endpoint can be judged by sheet test, drop test, refractometer, and thermometer.

-

- Sheet test:– A small portion of jelly is taken out during boiling, in a spoon or wooden ladle and cooled slightly. It is then allowed to drop. If the product falls off in the form of a sheet or flakes instead of flowing in a continuous stream or syrup, it means that the end-point has been reached and the product is ready, otherwise, boiling is continued till the sheet test is positive.

- Drop Test:- A drop of a concentrated mass is poured into a glass containing water. Setting down of the drop without disintegration denotes the end-point.

- Temperature Test:- A solution containing 65% TSS boils at 105o Heating of the jelly to this temperature would automatically bring the concentration of solid to 65%. This is the easiest way to ascertain the end-point.

- Removal of scum: – We have to add one teaspoon full of edible oil added for 45 kg sugar. If the scum is not removing the jelly becomes cloudy. When the scum is not removed before pouring.

- Addition of color and preservatives

- Filling in a sterilized jar: – The hot solution is poured into a sterilized container. So as to reduce the time of contact b/w pectin acid and boiling sugar.

- Sealing: – The container is sealed by an airtight sealing machine.

- Storing: – This is the last step in processing jelly. The container is stored at 25 to 35 degree C (at ambient temperature).

Defects in jelly

- Crystals in Jelly

Sugar crystallization may result from:

- Too much sugar

- Too little acid

- Overcooking of jelly

- Too long a delay in sealing the container of jelly.

Crystals may sometimes be found in jelly because, during the boiling, syrup spatters on the side of the pan and dries up. In subsequent pouring of the finished product, these crystals (act as seed material) are carried into the glasses of jelly.

2 Cloudy jelly

Usually occurs with red juices. It is caused by imperfect straining. Restraining of juice without pressure brings a lower yield, but ensures a clear product.

3 Failure to gel

Improper balance of pectin, acid, sugar, and mineral salts, which may come about in several ways:

- Fruit used may lack sufficient pectin or acid or both

- Overcooking may destroy so much pectin that a gummy mass is formed

- Undercooking, due to insufficient concentration

- Too much water is used for the extraction of juice, so that the proportion of sugar is too great for the pectin and the long time required for evaporation may destroy some of the pectins.

4 Tough Jelly

The jelly becomes tough or stringy when too little sugar is used for the quantity of fruit juice used or when boiling is continued after the jellying point has been reached.

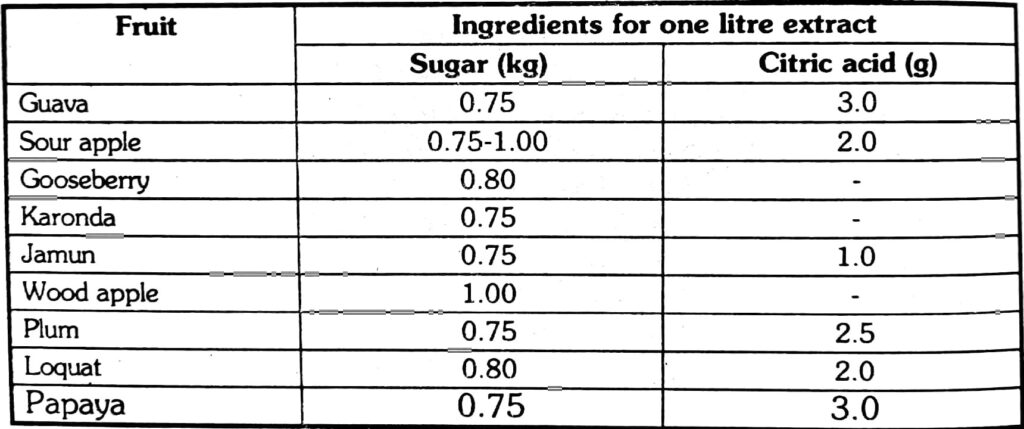

Guava Jelly

Ingredients:-

Guava – 1 kg

Sugar – 0.750 g

Citric acid- 3.0 g

Process

Fruit (Firm, not overripe) → Washing → Cutting into thin slices → Boiling with water (1 ½ time the weight of fruits for about 20-30 min) → Addition of citric acid during boiling (2 g per kg of fruit) → Straining of extract → Pectin test (for the addition of sugar) → Addition of sugar → Boiling → Judging of endpoint (sheet/drop/temp test) → Removal of scum (or) foam (one teaspoonful of edible oil added for 45 kg sugar) → Addition of colour and remaining citric acid → Filling hot into clean sterilized bottles → Waxing (paraffin wax) → Capping → Storage at ambient temperature.