Unfermented beverages

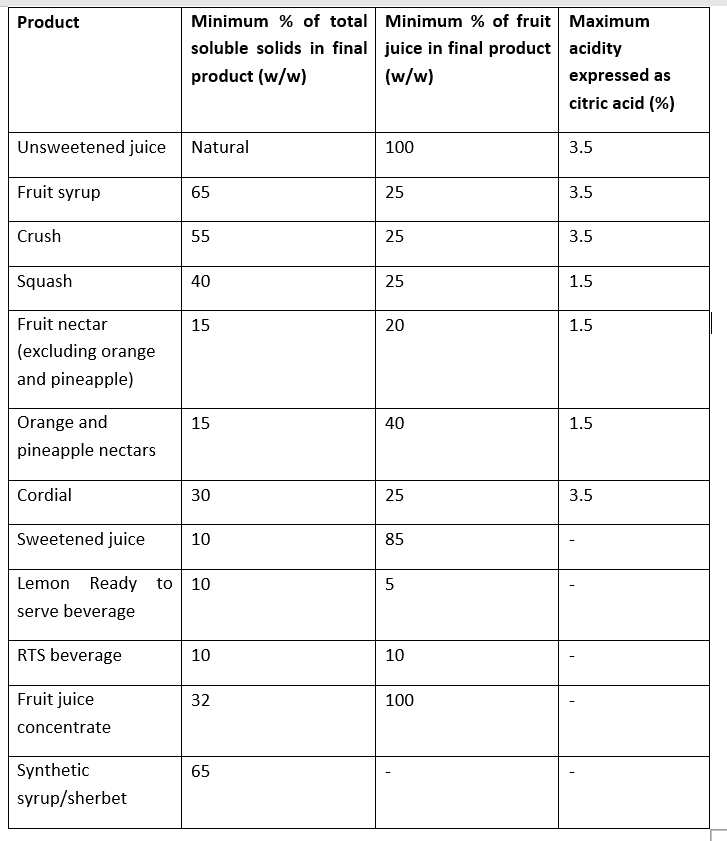

Fruit juices that do not undergo alcoholic fermentation are called unfermented beverages. These include natural fruit juice, sweetener, ready-to-serve drink (RTS), nectar, cordial, squash, crush, syrup, fruit concentrate juice and fruit juice powder. The minimum standards prescribed under the Food Safety and Standards Regulations, 2011 and the Fruit Products Order (FPO) are given in the table below:

Watch Lecture Video Part Ist

1. Fruit juice: It is a natural juice that is extracted from fruits and remains practically unchanged in its composition during processing and preservation. It is also called unfermented fruit juice or pure fruit juice, for example, apple juice.

2. Fruit Juice Beverage: It is a fruit juice that changes significantly in composition during preparation. It may or may not be diluted before consumption. Ready-to-serve (RTS) drinks, nectar, squash, cordial, and appetizer are all fruit juice drinks.

Watch Lecture Video Part IInd

3. Synthetic Beverages: Synthetic drinks are prepared by using sugar, water, flavourants, acidulants, colours, etc. These drinks do not contain fruit juice or pulp.

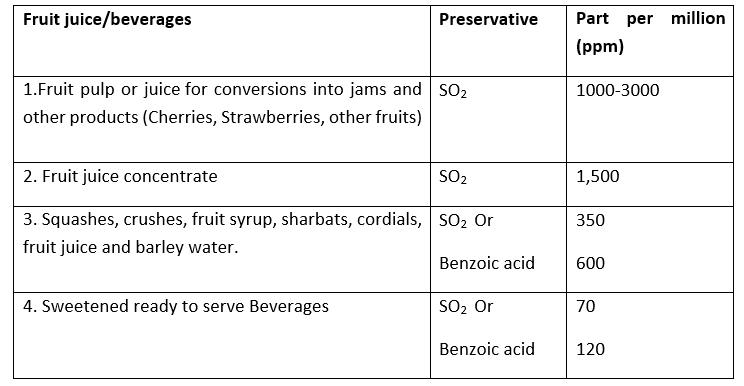

4. Ready-to-Serve (RTS) Beverage: It is a type of fruit drink that contains at least 10% fruit juice (5% juice for limes) and less than 10% TSS. The acidity in these drinks should not exceed 3.5% in the form of citric acid. RTS beverages are preserved using Class II preservative 70 ppm SO2 or 120 ppm benzoic acid. It is not diluted before serving so it is known as ready to serve drink for example mango drink, guava drink, pineapple drink, etc.

5. Fruit Nectar: This type of fruit drink contains at least 20% fruit juice or pulp and 15% total soluble solids and is preserved by heat processing. Acidity in fruit juices should not exceed 1.5%. As per the Indian food laws, no Class II preservative such as SO2 or Benzoic acid is allowed in fruit nectar. It is not diluted before use.

6. Squash: Fruit squash consists of the juice or pulp of the fruit to which sugar is added for sweetening. According to the FPO, fruit squash should contain at least 25% fruit juice or pulp and not less than 40% TSS. It should not contain more than 350 ppm SO2 or 600 ppm benzoic acid as a class II preservative. The acid content in squash generally ranges between 1-1.5% but should not exceed 3.5%. The squash is usually diluted with water in a 1:3 ratio before serving. Lime, lemon, mango, orange, guava, and pineapple squash are produced commercially.

7. Fruit Juice Cordial: It is a sparkling, clear, sweet fruit juice from which the pulp and other suspended substances are completely removed. Contains at least 25% juice, 30% TSS, and not more than 350 ppm SO2 or 600 ppm benzoic acid as a preservative. It is also used for mixing in alcoholic beverages for example lemon juice cordial.

8. Fruit Appetizer: The fruit appetizer is similar to fruit squash, but also contains spices, and herb extracts. Spices such as black pepper, cumin, cardamom, ginger mentha extract, and salt are used to make the appetizer. They are also called spiced fruit squash. Plum and apricot appetizers are quite common.

9. Fruit Crush: Fruit Crush must contain at least 25% fruit juice or pulp, 55% TSS, and no more than 350 ppm SO2 or 600 ppm benzoic acid. It is diluted before serving.

10. Fruit Syrup: It is prepared by using at least 25% fruit juice or pulp and sweetened using sugar. Contain at least 65% TSS and not more than 350 ppm SO2 or 600 ppm benzoic acid as a Class II preservative.

11. Synthetic syrups: Heavy sugar syrup of 70-75% strength is used as the base for all synthetic syrups, which are flavored and colored with artificial flavors and colours. These may or may not contain fruit pulp or juice. Rose, sandalwood, almond, poppy seed, and kewra sherbet/syrup are quite common.

12. Carbonated fruit drink: It is a ready-to-serve fruit juice drink containing a variable amount of fruit juice, sugar, acid, etc., and adding carbon dioxide gas. Apple juice, lime, lemon, and grapefruit juice can be used to make carbonated fruit drinks. They are prepared either by the pre-mix or post-mix method.

13. Fruit Juice Concentrate: It is a fruit juice, which is concentrated by removing water by evaporation, freezing, or reverse osmosis. Many products can be made from fruit juice concentrate. Apple juice concentrate, orange juice concentrate, etc. are prepared commercially in the industry.

14. Fruit Juice Powder: It is a fruit juice that has been converted into a fine powder. They can be prepared by the process of either freeze-drying, foam mat drying, or spray drying. These are easily reconstituted to obtain full-strength fruit juice drinks.

15. Barley Water: Fruit drinks that contain at least 25% fruit juice, 30% TSS, and 0.25% barley starch are called barley water. It also contains about 1.0% acid. Barley water is prepared from citrus fruits such as lemons, limes, grapefruits, and oranges, and most of these use lemons and lime.

It is prepared using about 1 liter of fruit juice, 2.0 kg of sugar, 15 grams of barley flour, and 1.3 liters of water.

Preparation of fruit juice beverages

Fruit selection: Not all fruits are suitable due to difficulty in extracting juice or poor quality juice. The variety and maturity of the fruit and the region of cultivation affect the taste and quality of its juice. Only fully ripe fruits are selected. Overripe and unripe fruits adversely affect the quality of the juice.

Sorting and Washing: Diseased, damaged, or rotten fruits are removed. Dirt and spray residues of arsenic, lead, etc. are removed by rinsing with water or using dilute hydrochloric (HCl) acid (0.5%) solution and then rinsing in water.

Juice Extraction: Usually the juice is extracted by crushing or grinding the fruit and pressing the crushed mass into a basket or hydraulic press. The juice can also be extracted using a screw-type juice extractor. Common equipment used for extracting juice is a fruit grater or mill, basket or hydraulic press, screw type juice extractor, rosing or burring machine, fruit pulper, etc. There are two methods of juice extraction, single and double operation system.

Single Operation: In a single operation, screw-type, plunger type, or roller-type presses are generally used for crushing and pressing the finished fruits for extracting juice. Citrus fruit segments are inserted through a hopper, passed through conical screws and juice flows through the pores while pomace emerges at the end of the conical jacket. The screw-type extractor is operated either manually or by using electricity depending on the requirement. The juice extracted is usually thick and cloudy and contains a considerable amount of macerated pulp. Care must be taken to remove the rind of citrus fruits completely otherwise it makes the juice bitter. The juice of citrus fruits like lemon, kinnow, etc. can also be extracted using the rosing or barring machine. Finally, strain the juice with a coarse cloth or sieve to remove the seeds.

Double Operation: In this system, the fruits are first crushed and then pressed separately. Fruits like apple, aonla, Jamun, grapes, berries, phalsa, etc. are crushed in a fruit grater or crusher and the crushed mass is pressed through a basket press and hydraulic press.

The procedures for juicing some fruits are variable:

- Soft fruits such as berries or tomatoes can be pressed through a fruit press or pulped using the juicer attachment to a food processor.

- The clear juice is usually extracted from citrus fruits.

- Hard fruits like pineapple are peeled, pulped, and pressed to extract the juice.

- The fruits of apple and pear are crushed in a fruit grater and pressed in a hydraulic/basket press to extract a clear juice.

- Passion fruit juice is prepared using a pulper-finisher that separates the skin and seeds from the pulp.

Fruits such as mango, guava, apricot, peach, etc., from which clear juice is difficult to extract, are passed through the pulper to form the pulp and then the pulp is used to prepare juices, fruit drinks, and beverages.

Deaeration: Freshly extracted juice contains a sufficient amount of oxygen which can affect the quality of the juice if not extracted before packing. The air in the juice is due to the presence of intracellular space present in the fruit. Most of the air as well as other gases are removed by subjecting the fresh juice to a high vacuum. This process is called deaeration and the equipment used for this purpose is known as a deaerator. Heating the juice during heat processing also helps to remove air.

Clarification of juices: The juices of fruits and vegetables are clarified using different methods.

- Straining or screening: Impure and unclarified fruit juices contain varying amounts of suspended substances including broken fruit tissue, seeds, skin, pectic matter, and proteins in colloidal suspensions. The seeds and skin, which adversely affect the quality of the juice, are removed by sifting through a muslin cloth or sieve. In small-scale industry, fruit juice is filtered through a muslin cloth or stainless steel mesh sieve to remove coarse particles. But in large industries power operated screening systems or filter presses are used.

- Finishing: Finishing is needed to remove the cloudiness of the citrus juices. The pulp is separated from the finisher juice by the action of a drill moving inside a cylinder screen. Screen holes range in size from about 0.020 to 0.030 inches in diameter, depending on the condition and tenderness of the fruit. Finishing is measured by the amount of pulp in citrus fruit juice.

- Decantation: The simplest method of cleaning is that the solidified juice is allowed to settle and then the clear juice is decanted or siphoned out. Keeping the juice at a low temperature for a long period of time helps the settle down the solid of the juice resulting in a pure juice.

- Centrifugation: The cloud particles can be separated by centrifugal action. The juice containing the solids is then poured into a basket or disc-type centrifuge, where centrifugal force separates the light and heavy components in each layer. The clear juice is collected and the unwanted solids are separated.

- Enzymes: Plant carbohydrates, pectin, starch, and proteins form colloidal suspensions in freshly extracted fruit juices. The pectinol enzyme is widely used to achieve better juiciness as well as for the purification of fruit juices as it breaks down the pectin into a soluble form which frees the suspended particles and settles down to clear the juice. leave. Similarly, proteolytic and starch liquefying enzymes i.e. amylase is used to remove proteins and starch from fruit juices. Pectinol is more effective in the case of acidic juices. Fruit juice can be purified in about 1-2 hours at 40-50°C temperature but requires 20 hours at 20°C temperature.

- Physical Finishing: Some finishing agents that have physical or mechanical action are known as kaolin, diatomaceous earth, Spanish clay, bentonite, or china clay and filter. Generally, 0.5 to 0.1 percent soil is mixed with fruit juice and passed through a filter press. Ultrafiltration is a process that separates the particles on the basis of molecular weight and better retains the nutrients in the juice. It is necessary to enzymatically set down the pectin prior to ultra-filtration to reduce viscosity and obtain a satisfactory juice.

- Chemical finings: Gelatin and casein are used to clarification of fruit juices and act partly to neutralize electrically charged particles and partly to form an insoluble precipitate with the components of the juice. Gelatin combines tannins and casein with the juice’s acids. Gelatin can be cloudy juice if used in excess. Depending on the amount of tannin in the fruit juice, the gelatin solution is added and allowed to stand for 18 to 24 hours to ensure that the precipitate settles down together. Then the clarified juice is siphoned off. Albumin (egg whites) can also be used for juice clarification.

- Clarification by freezing: Clarification by Freezing: Grapefruit juice contains cream of tartar or potassium hydrogen tartrate as well as pulp and skin which are removed by freezing or by cooling for long-term storage or by refrigeration. By this method, apple juice is precipitated on thawing and then it can be clarified.

- Clarification by heating: During heating, the colloidal material in the fruit juice becomes coagulates and settles down on cooling which can be separated using a filter press. To clarify apple and pomegranate juice, the juice is heated to 80-85°C for a few minutes and immediately cooled, and then the juice is filtered through a filter press.

Addition of sugar: All juices except grape and apple are sweetened by adding sugar. Sugar can be added directly to juice or as a syrup made by dissolving in water. The pulp or juice of fruit squash, cordial, and syrup is made by using cane sugar in appropriate quantities. Similarly, ready-to-serve drinks (RTS) and fruit juices are sweetened with cane sugar.

Fortification: Juices, squash, syrups, etc., are sometimes enriched with vitamins to enhance their nutritive value, improve taste, texture, or color, and replace nutrients lost in processing.

Typically, ascorbic acid and beta-carotene (the water-soluble form) are added at the rate of 250–500 mg and 7–10 mg per liter, respectively. Ascorbic acid acts as an antioxidant and beta-carotene provides an attractive orange color. Some acids are added for a balanced taste. Citric acid is often used for all types of beverages and phosphoric acid for cola-type drinks.

Preservation of juice: Fruit juices, RTS, and Nectar are preserved by pasteurization or by using chemical preservatives. Squash, crush, syrup, and cordial are preserved by adding chemical preservatives such as potassium metabisulfite or sodium benzoate.

Pasteurization: The most common method is to preserve fruit juices by heat. Pasteurization is a process in which the juice is heated to 100°C or slightly below to inactivate or kill the micro-organisms that spoil the juice. Fruit juices are typically pasteurized between 75 and 88°C, with periods ranging from 30 seconds to 30 minutes depending on the type of heating system, the nature of the juice, and the size of the container. Pasteurization can be done either by heating for a long time at a low temperature (LTLT) or by heating at a high temperature for a short time (HTST). Commonly adopted methods are:

- Holding pasteurization: In this method, the finished juice is filled into glass bottles with proper headspace, and the bottles are sealed airtight. After sealing the bottles are pasteurized. However, this method is not used for commercial-scale products.

- Pasteurization by overflow method: In this method, the juice is heated to a temperature of about 2.5°C above the pasteurization temperature and filled into hot sterilized bottles. Care must be taken to maintain the temperature during filling and sealing. Sealed bottles are processed in boiling water for a specified period of time. After processing the bottles are cool. When cooled, the juice shrinks leaving a small headspace in the bottle that holds no air. This method is used commercially for the preservation of all types of juices in the food industry.

- Flash pasteurization: In this process, the juice is heated for only a short time at a temperature approximately 5.5oC higher than the pasteurization temperature, filled into containers, sealed in the air under a steam cover to sterilize the seal, and then cooled. This process is also known as HTST (High Temperature and Short Time) method and the juice is heated rapidly. Flash pasteurization helps to reduce taste loss, better retention of vitamins, keep the juice cloudy evenly and reduce the ripe taste of the juice.

Aseptic Processing and Packaging of Fruit Juice: Aseptic processing and packaging is defined as the process in which a commercially sterilized product is packaged in a pre-sterilized container in a sterilized environment. This method involves high-temperature short time (HTST) sterilization of acidic products (pH < 4.6) over a temperature range of 90–110 °C and ultra-high temperature (UHT) sterilization at 121 °C for low acidic foods (pH > 4.6). is used. The commercial aseptic sterilization process takes place in a continuous, closed system. Aseptic processing can produce products with better nutrient retention and excellent sensory quality. Apple, Mango, Litchi, Pineapple drink, etc. in Tetra Pack are commercially processed using aseptic processing and packaging system.

Preservation with chemicals: The two most commonly used chemical preservatives are:

(i) Benzoic acid (benzoates)

(ii) Sulphur dioxide (Sulphites).

- Benzoic Acid:

- Benzoic acid is an effective agent but less soluble in water, so its sodium salt, which is soluble in water, is commonly used.

- Benzoic acid is more effective against yeast than moulds. However, it does not inhibit lactic acid and acetic acid fermentation.

- The amount of sodium benzoate required depends on the nature of the juice, its acidity, and the type of microbial infection.

2. Sulphur dioxide:

- Potassium meta-by-sulphite (K2O2SO2) is commonly used as a source of sulphur dioxide.

- In addition to fruit juices or drinks, it reacts with the acid of the juice and forms potassium salts and sulphur dioxide, which liberate and form sulphurous acid with the juice’s water.

- Sulphur dioxide is more effective against mould spores and bacteria than yeast and also inhibits enzymes etc.

- It acts as an antioxidant and bleaching agent and thus helps in the retention of ascorbic acid, carotene and other oxidizable compounds.

- It also prevents non-enzymatic browning or discoloration of the product.

- Its effectiveness depends on the acidity, pH, temperature and other substances present in the fruit juice.

- SO2 should not be used in naturally colored juices such as phalsa, jamun, pomegranate and strawberry, as it has a bleaching action.

- It should also not be used in juices that are to be packaged in tin containers, as it can act on the tin of the containers, forming hydrogen sulphide and black compounds.

- For preservation, potassium meta-by-sulphite must first be dissolved in a small amount of water and then added to the juice.

- Preservation by sugar: Fruit juices containing 66% sugar usually do not ferment. Fruit syrups or sharbat with high total solids (65% and above) have very little working water, so microorganisms cannot grow. Sugar acts as a preservative by osmosis and inhibits the growth of micro-organisms. However, mould and yeast growth may occur on the surface of jams or jellies, which need to be protected by using airtight packing or by covering the product with melted paraffin wax.

- Preservation by freezing: A properly stored juice retains its freshness, colour, taste, and aroma for a longer period of time. The deaerated juice is transferred to containers, which are hermetically sealed and frozen. Freezing does not sterilize fruit juice, it only lowers the temperature to the point where microbes do not multiply and the chemical changes occur very slowly.

- Preservation by drying: Microorganisms require water for their growth and multiplication and as soon as the water is removed, they become incapable of multiplication. Fruit juices can be preserved in powder form by different methods, such as spray drying, drum drying, freeze-drying, foam-mat drying, etc. Fruit juice powders are highly hygroscopic and require special care in packing. It should be packaged as free-flowing powder in hermetically sealed containers with desiccant to prolong the shelf-life of the product. Lemon juice powder can also be prepared using the foam mat drying process.

- Preservation by Carbonation: Carbonation is a process of mixing carbon dioxide under pressure with water, juice, or beverages so that the product is served; Release the gas in fine bubbles and produce a distinctive taste. Carbonated drinks are typically bottled with a carbon dioxide content of 1 to 8 g/l.

- Preservation by Filtration: In this method, clear fruit juices (especially apples and grapes) are passed through special filters which are capable of retaining yeast and bacteria. Various types of germ-proof filters are used for this purpose and this method is used for soft drinks, fruit juices, and wines.

Filling and Processing: The bottles are rinsed thoroughly with hot water and filled leaving 1.5-2.5 cm headspace. Bottles intended for heat processing are sealed using crown corks while bottles that are shielded using chemical preservatives can be sealed using PP (Pilfer Proof) caps.

Fruit juice powders:

The fruit juice powder process involves drying the water from the fruit juice by evaporation. These powders are highly hygroscopic in nature and hence require proper packaging. These powders are prepared from strained fruit juices by different drying techniques such as spray drying, double-drum drying, vacuum drying, freeze-drying, and foam-mat drying. The powder has a long shelf-life and is soluble in cold water. Reconstitution of the powder can yield full-strength fruit juice drinks.

Much of the distinctive fresh flavor is lost during the drying process, which is compensated by the addition of natural fruit flavorings in powder form. Mango, orange, lemon, guava, passion fruit and tomato juice can be dried and powdered.

Fruit juice concentration :

Concentration is a process of extracting water from the juice to increase the concentration of soluble solids in fruit juice. Processing such as spray drying or drum drying is also used to pre-concentrate the juice for further use. Concentrates for processing have significant advantages, reducing storage, packaging, and transportation costs, while the concentration of soluble solids aids in preservation by reducing water activities. Juice concentrate can also be used as a base material for making various food and beverages. The juice can be concentrated by evaporation, using reverse osmosis to freeze the concentrated juice.

Evaporation is most commonly used to prepare apple juice concentrates on a commercial scale. The evaporator consists of a steam-filled heat exchanger to heat the fruit juice to the desired temperature for evaporation. There is a separator from which the vapor is separated from the concentrated liquid phase, a condenser to affect the condensation of the vapor and its removal from the system, and a still part for the recovery of the aroma. Generally, falling film evaporation is used to concentrate apple juice. The final concentration is done in a centritherm evaporator. Apple juice is concentrated to 6-7 times its initial total soluble solids. The apple juice is immediately cooled and stored in cold stores in large barrels. In particular, pure fruit juice concentrates of orange, apple, pineapple, and grapefruit are highly popular.

Advantages of Concentration and Evaporation

- Less weight than fresh juice and lower costs in bulk packaging, storage, and transportation.

- The entire crop of fruits can be fully utilized during the peak season, helping to reduce the prices.

- The product can be used as a base material for making various beverages.