Harvesting

This is the separation of a product from its original place. This point of origin can be part of the plant above ground i.e. shoot example apple, tomato, etc., or an underground plant part-like potato, carrot, etc.

This involves separating the product from the parent plant by hand or with a tool or machine.

Harvesting Methods

Several factors are considered in deciding the appropriate harvesting method. There are two methods of harvesting. They are (1) hand harvesting and (2) mechanical harvesting.

Watch Lecture Video Part 1st

Watch Lecture Video Part 2nd

-

Hand harvesting

All horticultural crops have been harvested by hand since ancient times. Some crops eg. Even today flowers are plucked by hand. Hand harvesting is still the most common method for horticulture produce in India due to inadequate mechanization, smallholdings, and the diversity of crops grown by small farmers. In developing countries, most products for internal rural and urban markets are harvested by hand.

Advantages of hand-harvesting:

- Hand harvesting is common in those crops in which the product has to be harvested at different stages of maturity and the crop is harvested several times.

- Ripe fruits can be precisely selected

- Precise grading (removing of damaged, diseased fruits at the time of harvesting)

- Less expensive

- Minimal damage to the product

- The rate of harvesting can be increased by employing more people.

- Minimum capital investment.

- The same worker can be used for harvesting different types of crops viz. Apple and gladiolus can be plucked by the same person but cannot be harvested by the same machine.

- Immature or small-sized fruits can be left on the plant for the next crop like peas, capsicum.

Disadvantages of hand-harvesting:

- More time consuming

- Dependent on availability of labour.

2. Mechanical Harvesting

It is very useful in the low-cost and fast harvesting of a particular crop. Special harvesting machines are designed for specific crops. Mechanical harvesting is common for most crops in developed countries but is still uncommon in India. Machine harvesting is usually viable only when the entire crop is to be plucked or harvested at once.

Advantages of mechanical harvesting:

- Fast harvesting thus saves time

- Less dependency on labor availability

- Improving working conditions for the worker.

Disadvantages of mechanical harvesting:

- Requirement of skilled manpower for use of the machine, hence the dependence on trained manpower.

- Improper use of the machine can cause huge economic losses

- The machine requires regular maintenance

- May damage perennial crops (bark of tree branches)

- Social impact from lower labor requirements and employment

Harvesting Machine

Mechanical harvesting devices employ direct contact methods such as combing, cutting, pulling, snapping, twisting, stripping, and compacting.

-

Shake-Catch and Collect System

It was designed for harvesting fruits of deciduous trees, grapes, and blueberries. The system consists of a vibrator to move the fruit off the plant and the fallen fruit is caught in a built-in frame and collected in boxes.

-

Pick and collect system

It picks up fruit from the ground surface and was designed for harvesting walnuts, almonds, pecans, and filberts. Fruits, which naturally fall on the ground or which are plucked by shaking, are collected by this system. It is a labour-saving device.

-

Once-over harvesters

These were designed to harvest vegetable crops grown for canning and pickling, such as peas, snap beans, tomatoes and cucumbers. All the fruits on the plant are harvested in one operation. The type of machine used varies with the crop. As with peas, the vines are cut at the base and the pods are separated in a machine called a “viner”. With snap beans, rotary tines, or fingers attached to a reel or chain work from top to bottom of the plants as the machine progresses. The tines-like fingers separate the beans from the plants and place them on a moving conveyor belt, which carries them to the boxes. The base stems along with the tomatoes and cucumbers are cut off and are moved to the tops compartment of the machine, which shakes the fruit off the vine. All ripe and other unwanted fruits are removed by hand.

Preparing to harvest

- A poor harvesting operation will result in poor quality yield and low selling price. The producer should plan the harvesting operation/work very carefully, especially when the enterprise is at a commercial scale. Arrangements for workers, equipment, and transportation should be made. Harvesting equipment must be cleaned and prepared for operation.

- When the crop is ready for harvesting, the decision on when to start harvesting will largely depend on this;

- Weather conditions

- Market interest

- The flexibility of marketing date. It depends on the crops. For example, some such root crops can be harvested and stored in the field waiting for favorable prices, and can be sold for a longer period. Other products like soft berries should be marketed as soon as they are ready or else they will go spoil.

Post-harvest handling of fruits and vegetables / Field Handling

Post-harvest handling is the name given to all the processes through which fruits and vegetables are delivered from the time of harvest to the consumer.

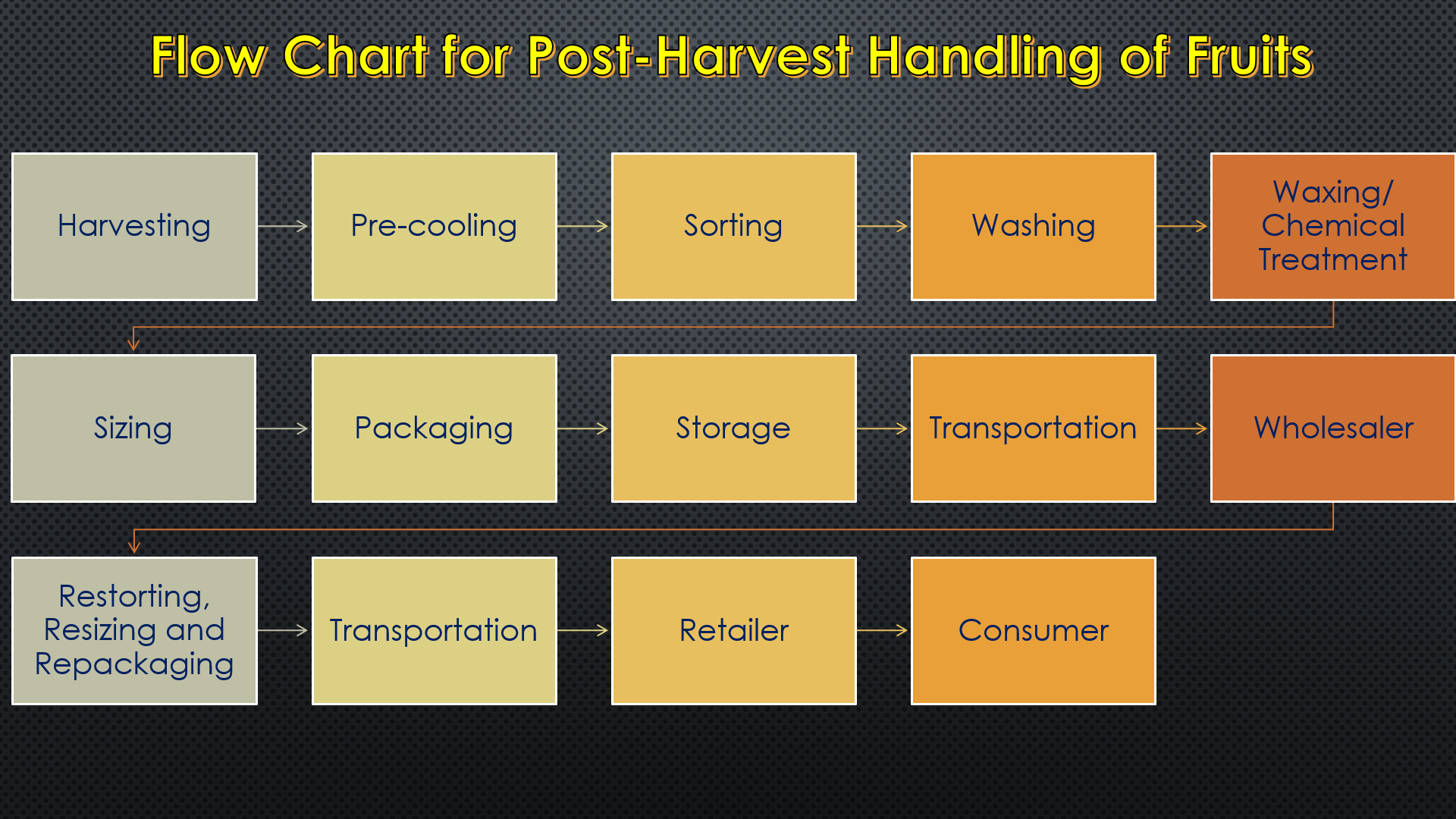

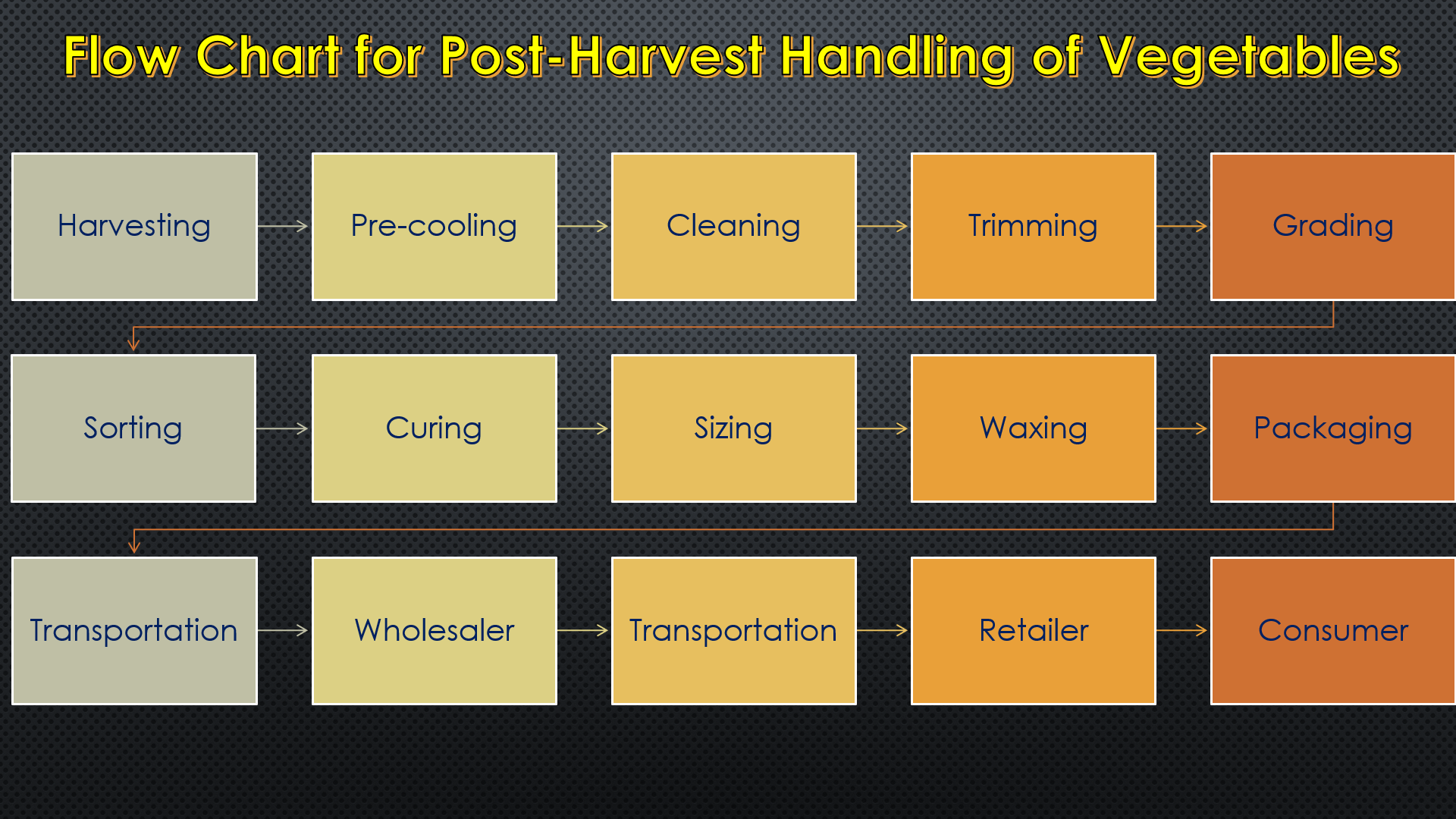

Flow Chart for Post-Harvest Handling of Fruits and Vegetables

Flow Chart for Post-Harvest Handling of Fruits

Flow Chart for Post-Harvest Handling of Fruits

1) Pre-cooling:

High temperatures are detrimental to maintaining the quality of fruits and vegetables, especially when harvesting is done during hot days. Pre-cooling is a means of removing the heat of the field. This slows the respiration of the product, reduces the risk of micro-organism attack, reduces water loss, and reduces the load on the cooling system of storage or transportation.

Currently used pre-cooling methods include room cooling, forced air cooling, water cooling, vacuum cooling, and package icing.

a) Room cooling:

This is a relatively simple method that requires only one refrigerated room with sufficient cooling capacity. Products are packaged in containers, which are placed loosely in the cooling room, leaving enough space between the containers to allow cool air to circulate for each. The rate of cooling is slow as compared to other methods of cooling. All fruits and vegetables such as bananas, beans, cabbage, coconut, garlic, ginger, lemon, onion, orange, cucumber, pineapple, potato, pumpkin, radish, sweet potato, tomato melon are pre-chilled with this method.

b) Forced air cooling:

This is a more rapid method of air cooling the product. Cold air is forced to flow through the inside of each container, causing it to carry heat away from the surface of the product rather than directly onto the surface of the container. The containers are placed inside a covered tunnel with an exhaust fan at one end. Highly perishable and high-value products such as grapes, strawberries, and raspberry berries can be refrigerated in less than an hour using this method.

c) Water cooling (Hydro cooling):

This is a faster and less expensive method. The product is then exposed to cold water through a bath or dip. The required cooling time is often minutes. However, not all types of products tolerate hydrocooling. In hydro-cooled products, the surface becomes wet which can encourage decay in some types of products.

Certain leafy vegetables, artichokes, asparagus beets, broccoli, Brussels sprouts, carrots, cauliflower, celery, Chinese cabbage, cucumber, eggplant, green onions, kiwifruits, leeks, oranges, parsley, and peas. Pomegranates, radishes, spinach, rhubarb, swiss chard, summer squash, etc. are pre-cooled by this method.

d) Vacuum cooling:

This is the most efficient method for cooling leafy vegetables, especially vegetables such as lettuce, cabbage, and Chinese cabbage. The product is placed inside a vacuum tube with low air pressure. When the pressure is reduced to 4.6 mm Hg, the water boils over the entire surface of the leaf at 00 C. The effect of boiling draws heat to vaporize and therefore cools the product. The cooling time is usually 20-30 minutes. The equipment required for vacuum cooling is very expensive, and may not be a good choice for doing small scale.

Some stem, leafy and flowering types of vegetables such as endive, Brussels sprouts, carrots, cauliflower, Chinese cabbage, celery, leeks, lima beans, spinach, sweet corn, etc., are pre-cooled by this method.

e) Package-icing or top icing:

Package-icing or top icing: This is the easiest way to cool. The product may be cooled by adding crushed ice, flaky ice, or ice slurry to the containers. However, this method is not suitable for products that are very sensitive to ice-cold temperatures. Cooling by ice also inevitably moistens both the produce and the container and generates water that needs to be removed.

Roots, stems, flowering vegetables like endive, broccoli, Brussels sprouts, carrots, onions, Chinese cabbage, leeks, parsley, spinach, sweet corn, etc. are pre-cooled by this method.

(2) Curing:

This is done immediately after harvesting. It strengthens the skin. The process is induced at relatively high temperature and humidity which involves sterilization of the external tissues followed by the development of the wound periderm which acts as an effective barrier against infection and water loss. Potatoes, sweet potatoes, colocasia, onions, garlic are cured before storage or marketing.

This condition occurs quickly in sweet potatoes at a high temperature of 330 C and relative humidity of 95%. Potato tubers are kept at 18°C for 2 days and then at 7°C-10°C for 10-12 days at 90% relative humidity. Curing also reduces the moisture content, especially in onions and garlic. Drying the superficial leaves of onion bulbs can protect them from microbial infection in storage. The maximum safe temperature for field curing of onion is 37.8°C for 3-5 days.

(3) De-greening:

It is typically the process of using ethylene or other similar metabolic inducers to break down the green pigment in fruits to give the fruit a distinctive color preferred by the consumer. It is used in bananas, mango, citrus, and tomato. De-greening is carried out in special treatment rooms with controlled temperature and humidity using a low concentration of ethylene (20ppm) to keep CO2 levels below 1% (low color). Ethylene must be supplied from a gas cylinder. These rooms are well ventilated to keep carbon dioxide levels below 1%, which hinders high color. Ethylene accelerates the decomposition of chlorophyll without significantly affecting the synthesis of carotenoid pigments. The suitable de-greening temperature is 27° C. Higher temperatures delay de-greening. Relative humidity should be 85-90%. High humidity levels cause condensation during de-greening and slow de-greening and increase decay. Low humidity however prevents decay, excessive shrinkage, and cracking of the rind.

(4) Washing and drying:

Most fruits and vegetables are washed post-harvest to improve their appearance, prevent wilting, and reduce primary infection of microorganisms. Therefore, fungicide or bactericide should be used in washing with water. Washing delays, the ripening of bananas thereby improving their shelf life. Excess water must be removed after washing otherwise it will encourage infection of microorganisms. Root and tuber crops are often washed to remove clogged soil.

(5) Sorting and grading:

Immature, diseased, and badly damaged fruits and vegetables are sorted. Most countries have their own standards for domestic trade and also have international trade standards.

Grades are based on size, weight, color, and shape. Grading is done manually or mechanically.

(6) Dis-infestation:

Papaya, mango, cantaloupe, and other fruits are susceptible to fruit fly attack. Insect infestation is carried out either by vapor heat treatment at 430 C (with air saturated with water vapor for 6-8 hours), by ethylene dibromide fumigation (with 18-22 g EDB/m3 for 2-4 hours). Inorganic bromide residue should not exceed 10Vg/g) or by cold treatment (exposing the fruit to near freezing temperature for a certain period of time)

(7) Postharvest treatments:

Post-harvest use of Bavistin (0.1%) and Topsin (0.1%) controls storage diseases in mango. In Nagpur Mandarin, hot water treatment with Imazalil (0.1%), Bavistin (0.1%) and Benalate (0.1%) are most effective. To obtain a complete inhibition of potato germination, cool chamber (evaporatively cooled) for 4 months and 5 months before completion of the dormant period in an aqueous emulsion of CIPC @ 50mg and 100 mg/kg tubers respectively is sprayed.

(8) Waxing:

Fruits and vegetables have a natural waxy layer on their outer surface that is partially removed by waxing. An additional layer of wax is artificially applied with sufficient thickness and consistency to provide the necessary protection against decay organisms to prevent aerobic conditions within the fruit. Waxing is especially important if small bruises and scratches are present on the surface of the fruit.

These can be sealed with wax. Waxing also enhances the luster of fruits or vegetables. Therefore, the form is improved to make them more acceptable.

If refrigerated storage facilities are not available, coating the protective skin with wax extends the storage life of fresh fruits and vegetables at ambient temperatures.

There are two types of wax emulsions. Wax ‘W’ does not add shine to fruits and vegetables, while Wax ‘O’ gives shine too.

The use of wax emulsions for freshly harvested healthy products protects them from excessive moisture loss, high rates of respiration, heat buildup, or thermal decomposition. The texture and quality of fresh produce are maintained as close to fresh conditions as possible for as long as possible.

Wax emulsions without fungicides do not protect fruits and vegetables from spoilage by microorganisms. Therefore, suitable fungicide is added to the wax emulsion to prevent the spoilage of fruits and vegetables due to microorganisms.

(9) Control of ripening process:

Ripening converts a physically mature but inedible plant part into an attractive taste and smell sensation. It marks the completion of growth and the onset of senescence with the life of fruit and is generally an irreversible event.

An adequate amount of ethylene for ripening should be used in the ripening room at regular intervals. Concentrations of CO2 above 1% delay ripening. Therefore, it is necessary to be thoroughly ventilated. By use of Ethephon commercially known as Ethrel, making it alkaline using caustic soda (3 g of soda for 20ml of ethephon). Calcium carbide (100 g for 100 Kg of fruits) can also be used for ripening. The ripening of fruits and vegetables can be retarded by proper packaging, low temperatures, ethylene absorbers, waxing, growth retardants, and using fungicides to control spoilage.

Frutox (Fungicide Vaxol) and Tal Prolong (1.0-1.5%) for delayed ripening in mango.

Frutox Tal is more efficient than Prolong which slows down ripening.

The use of Cycocel (500 mg/l), Alar (500 mg/l), GA (250 mg/l) significantly reduces ripening.

The application of PURFIL (alkaline potassium permanganate on silicate carrier) is effective in the complete absorption of ethylene in bananas kept in sealed polythene bags.

(10) Pre-packaging in plastic films:

This extends shelf life by creating a modified atmosphere with increasing CO2 concentration in the package. The packaging material should get the proper amount of oxygen. For this, suitable breathing films such as polystyrene and cellulose acetate are used. However rigid LDPE films that have higher O2 and CO2 transmission rates are more durable.

The pouch should have pores that allow the O2 and CO2 to circulate rapidly for the respiration of fresh produce. Used pouches reduce bruising, facilitate inspection, reduce moisture loss (weight loss) and prevent dehydration. It also creates modified environments.

(11) Palletization:

Pallets are widely used to transport packages of fruits and vegetables in all developed countries. Loading and unloading are very important steps in the post-harvest handling of fruits and vegetables but are often neglected. Loading and unloading in India are done manually. Due to the low unit load, there is a tendency for the package to be thrown, dropped, or mishandled causing damage to the item. This loss can be reduced to a great extent by using a pallet system. However; This requires standardization of box dimensions. For each object, this work must be done. Once this is accomplished, mechanical loading and unloading become much easier with a forklift system.

The advantages of handling packages on pallets are:

- The labor cost in the work is greatly reduced.

- The cost of transportation is reduced.

- Goods are protected and damage is minimized.

- Mechanized handling is much faster.

- Due to higher stacking, storage space can be used more efficiently.

- Pallets encourage the introduction of standard package sizes.

(12) Transportation:

In selecting the mode of transport, the distance to reach the destination, as well as the perishability of the commodity, should be considered. Highly perishable goods must have a much lower temperature during transport. Faster transport should be preferred for perishable goods than rail transport. Product for local transport is towed by bullock carts or tractor trolleys, the farm-used carts, trailers, and trucks must have good suspension and low air pressure in tires to avoid the excessive shock of production. They should be driven slowly. Laying straw or leaves in the trailer can also help prevent damage.

(13) Storage:

The marketable life of most fresh vegetables can be extended by quick storage in an environment that maintains product quality. Storage methods can be divided into two.

Conventional methods (low-cost storage structures) – in-situ, clamps, windbreaks, cellar storage, barns, night ventilation, sand and coir, night temperatures cool, natural ice, and well water cooling do.

Advanced methods (low-temperature storage-cold storage): hydro cooling, hypobaric storage, evaporative cooling, forced air cooling, controlled atmospheric storage, and modified atmospheric storage.

(14) Irradiation:

The application of radiation to suppress germination and hence to increase shelf life has been permitted in India. Onion sprouting can be inhibited by gamma radiation in the amount of 0.06-0.1 kGY. Gamma irradiation 0.1 kGY in potatoes can completely inhibit sprouting. Irradiated potatoes can be successfully stored for 6 months at 15 °C with a loss of 10%.

In banana, guava, mango, and papaya, irradiation improves shelf life by delaying the rate of ripening and senescence.